What are Amazon Vendor Central Purchase Orders and How to Understand Them

As an Amazon vendor, understanding purchase orders (POs) is essential for managing your relationship with Amazon and ensuring smooth operations. In this guide, you'll learn about the structure of purchase orders, how Amazon manages them, and how you can improve your performance to receive more POs. We've also included tips for improving your relationship with Amazon through efficient PO management.

What Are Amazon Vendor Purchase Orders (POs)?

A purchase order (PO) is a formal request from Amazon to a vendor to supply specific products in certain quantities. Managing POs effectively ensures timely product delivery and maintains a positive relationship with Amazon.

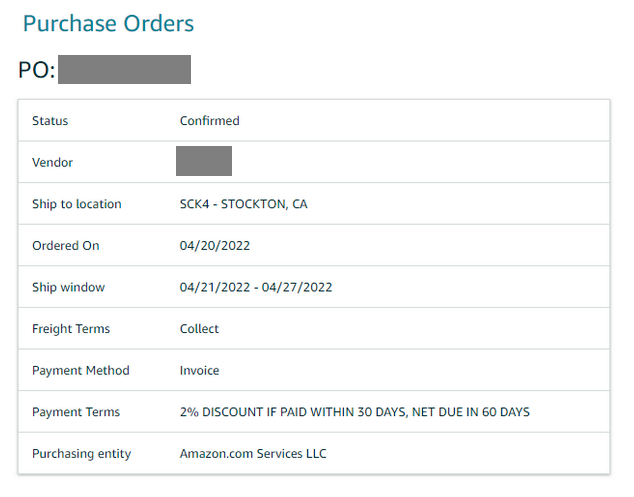

Anatomy of a Purchase Order

Each Amazon PO contains several key elements, including:

PO Number: A unique identifier for the order.

Product ASIN: The Amazon Standard Identification Number for the item.

Quantity: The number of units Amazon is requesting.

Shipping Window: The timeframe in which you must deliver the product.

Price: The agreed price Amazon will pay you for each unit.

These details form the foundation of your agreement with Amazon for that specific order.

EDI vs. UI vs. SP API

Amazon offers multiple ways to manage POs:

EDI (Electronic Data Interchange): A system that automates the exchange of POs and invoices between Amazon and your internal systems.

UI (User Interface): The manual method of managing POs through the Vendor Central dashboard.

SP API (Selling Partner API): A more flexible and automated API solution that allows you to integrate your internal systems with Amazon’s to streamline data management.

Vendors with higher sales volumes often benefit from implementing EDI or SP API for more efficient order processing.

How Amazon Updates POs and What to Expect

Amazon typically updates POs automatically based on stock levels, customer demand, and other factors. As a vendor, you should expect periodic updates to your POs, especially when lead times or delivery windows change. It's important to regularly check Vendor Central for any updates to avoid missing changes in shipping windows or quantities.

Key Metrics for Purchase Orders

Several metrics are crucial to managing POs effectively. These metrics help you evaluate how well you’re meeting Amazon’s expectations and highlight areas where you can improve.

Fill Rate

Lead time represents the period between when a vendor receives a PO and when they fulfill it, with shorter lead times benefiting Amazon’s lean inventory model by enabling rapid response to shifts in demand. Vendors who consistently deliver within short lead times are more likely to see a positive impact on order frequency and volume, as this efficiency strengthens Amazon’s supply chain and improves vendor reliability. Streamlining supply chains and enhancing logistics partnerships are valuable strategies for vendors aiming to reduce lead times.

Lead Time

Lead time represents the period between when a vendor receives a PO and when they fulfill it, with shorter lead times benefiting Amazon’s lean inventory model by enabling rapid response to shifts in demand. Vendors who consistently deliver within short lead times are more likely to see a positive impact on order frequency and volume, as this efficiency strengthens Amazon’s supply chain and improves vendor reliability. Streamlining supply chains and enhancing logistics partnerships are valuable strategies for vendors aiming to reduce lead times.

Inventory Availability

Inventory availability measures the extent to which a vendor’s products are in stock and ready for Amazon to fulfill customer orders. High inventory availability is crucial because it helps prevent stockouts, improves product rankings, and maintains customer satisfaction, all of which encourage Amazon to place more orders. Vendors can optimize inventory availability by analyzing demand data within Amazon’s retail analytics reports, allowing them to proactively adjust stock levels to align with Amazon’s stocking requirements and avoid overstocking or understocking.

Net Pure Profit Margin (Net PPM)

Net PPM reflects the profitability Amazon achieves from a vendor’s products, factoring in cost price, discounts, and vendor funding. High Net PPM products are prioritized by Amazon because they meet profit goals, making them more likely to receive frequent or larger POs. Vendors can optimize Net PPM by carefully balancing pricing, funding, and operational costs, focusing on strategies that enhance product margins and increase their appeal to Amazon’s purchasing teams

On-Time, In-Full (OTIF) Compliance

OTIF measures how frequently vendors deliver orders on time and in full, which is critical for Amazon’s ability to maintain stock levels and fulfill customer demand. A high OTIF compliance rate is essential not only to avoid penalties but also to maintain a strong scorecard with Amazon, as it demonstrates the vendor's reliability. Repeatedly missing OTIF targets can lead to lost PO opportunities, making it essential for vendors to align their logistics and inventory management processes to meet this requirement consistently.

Chargebacks

Chargebacks are penalties Amazon imposes when vendors don’t meet requirements related to shipping accuracy, labeling, packaging, and delivery timelines. These penalties can significantly reduce profit margins and strain the vendor’s relationship with Amazon if they become frequent. To minimize chargebacks, vendors should ensure that all shipments comply with Amazon's packaging and labeling standards, maintaining a rigorous quality control process to catch potential issues before they lead to additional costs.

Forecast Accuracy

Forecast accuracy assesses how well a vendor’s inventory levels align with Amazon’s demand predictions, with accuracy helping to prevent costly over- or under-stocking. By closely aligning with Amazon’s demand forecasts, vendors can ensure they have the right amount of stock on hand, which reduces the risk of lost sales due to stockouts or increased storage costs from excess inventory. Implementing predictive tools and regularly reviewing sales data can improve a vendor's ability to accurately forecast demand, supporting efficient inventory management.

Vendor Scorecard

The vendor scorecard aggregates performance metrics, including OTIF, fill rate, and chargeback rates, providing Amazon with a comprehensive evaluation of vendor reliability and compliance. High scorecard ratings increase the likelihood of receiving more POs and volume from Amazon, as they signal that the vendor can consistently meet Amazon’s operational expectations. Regularly reviewing the scorecard and addressing recurring issues can help vendors maintain or improve their scores, fostering a stronger partnership with Amazon.

Improving Your Relationship with Amazon Through POs

Maintaining a good relationship with Amazon often depends on how well you handle POs. Here are some ways you can improve your PO performance:

Meet OTIF Standards: Consistently delivering orders on time and in full will help you avoid chargebacks and maintain a positive vendor scorecard.

Improve Inventory Management: Ensuring you have enough stock to meet demand will help reduce the risk of stockouts and maintain a high fill rate.

Utilize Automation: Implementing EDI or SP API to manage POs can help streamline your operations, reduce human error, and improve your ability to meet Amazon’s requirements.

Monitor Your Metrics: Regularly review your vendor scorecard and key metrics like OTIF compliance and lead time. Identifying issues early can help you address problems before they affect your relationship with Amazon.

How to Get More Purchase Orders

To receive more POs from Amazon, consider implementing the following strategies:

Drive Demand: Increasing customer interest in your products can lead to more POs. This can be done by driving traffic to your product pages, improving product visibility, and maintaining strong customer reviews.

Create Scarcity: Limiting the availability of your products across other retailers and focusing on Amazon can increase demand from Amazon’s purchasing teams.

Offer Bulk Buys: Offering bulk purchase discounts or financial incentives may encourage Amazon to place larger or more frequent POs.

Leverage the Born to Run Program: If you're launching a new product, the Born to Run program allows you to submit a bulk PO for that product, increasing the likelihood of future orders.

By taking these steps, you can position yourself as a reliable vendor, increasing the likelihood that Amazon will place more POs with your company.

By focusing on accurate PO management and maintaining strong performance metrics, you can improve your relationship with Amazon and receive more purchase orders, ultimately driving growth for your business.

Amazon purchase orders are vital to the success of every vendor. They serve as the cornerstone of the transactional relationship between vendors and Amazon, making it crucial to comprehensively understand their intricacies.

Why is it important to solve purchase order-related challenges? The answer lies in the fundamental role that purchase orders play in the operations of Amazon vendors. They dictate the flow of products, influence inventory management, and impact revenue generation. Failing to navigate purchase orders efficiently can lead to missed sales opportunities, operational inefficiencies, and even financial penalties.

In this article, we’ll provide guidance to help vendors optimize their purchase order processes. From identifying signs of issues within organizations to implementing strategies for resolution, we aim to equip vendors with the knowledge and tools they need to navigate the world of Amazon Vendor Central purchase orders successfully.

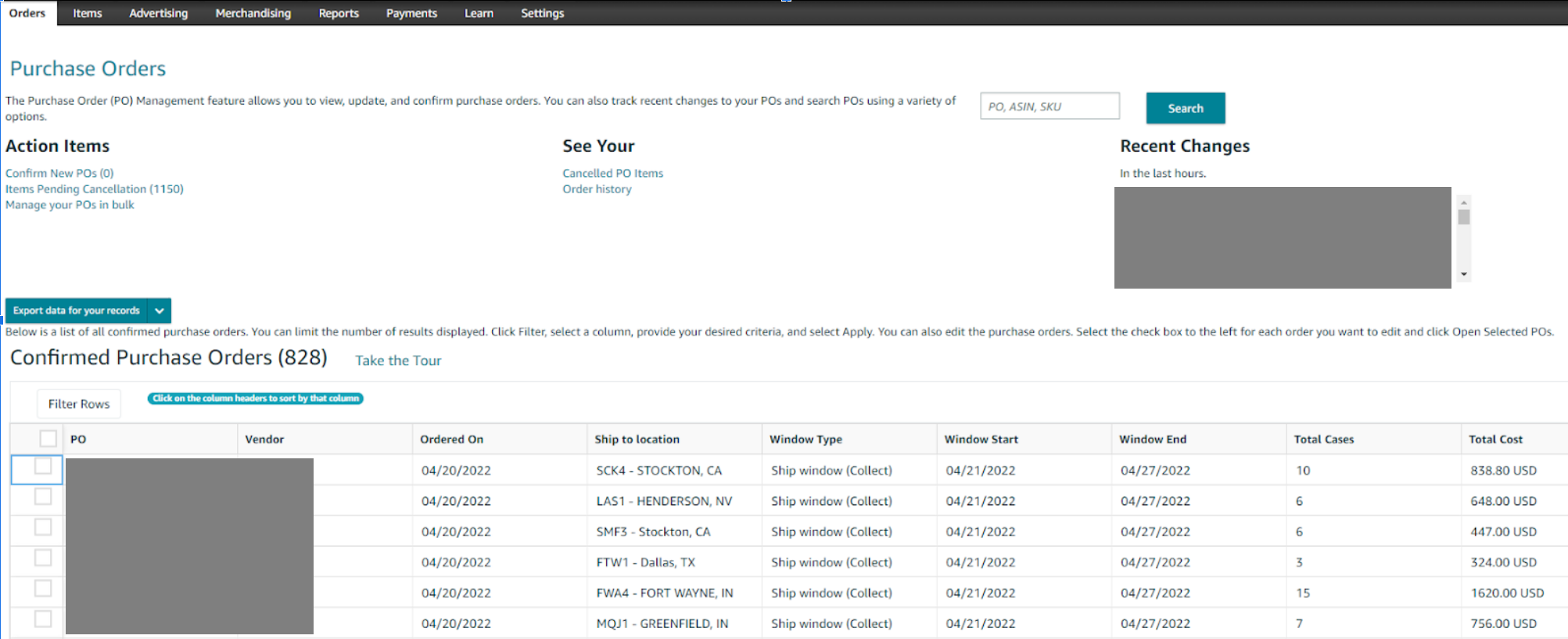

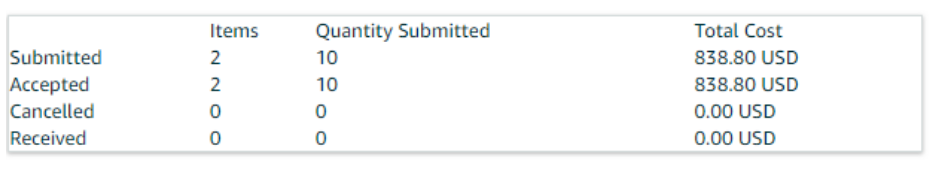

How Do I Track Confirmation Rates?

At each individual purchase order, you can find the quantity submitted and accepted. The confirmation or acceptance rate = accepted/submitted.

The Importance of the Shipping Window

Amazon will typically provide a shipping window for a vendor that confirms the PO. If a vendor confirms an order, it must meet that shipping window, which typically includes a handoff start date and an end date. In addition to confirmation rates, Amazon is closely monitoring how often vendors are shipping within these windows.

But shipping windows aren’t important just for staying in Amazon’s good graces: it also affects how quickly a vendor will get paid. A vendor can’t invoice Amazon for products purchased until that product has been shipped. So if you wait a day to ship a product, that’s another day added to the timeline to get paid.

How Do I Track the Shipping Window?

Ship windows can be found both on the purchase orders dashboard in Vendor Central as well in each individual purchase order.

How Vendors Can Get more Purchase Orders for higher volumes

If you feel like you could be doing better when it comes to POs, consider making some adjustments. After all, PO performance is a big driver on both your revenue and your relationship with Amazon.

Keep Products in Stock

A lot of times when vendors aren’t able to confirm purchase orders or ship within a certain window, it’s because they simply run out of stock of a product frequently. In that case, the vendor needs to focus their energy on recalibrating their stocking strategy to make sure a product is always in stock.

If you feel like you need improvement in this area, go back and look at historical order history and come up with some more accurate estimates of how much inventory needs to be on your shelves and when.

Retool Your Operations

Your business might benefit from setting up an EDI (electronic data interchange) feed with Amazon that better allows PO and invoice data to be exchanged between two servers. This will help you manage bulk ordering more efficiently, and give your PO confirmation rate a boost in the process.

If you're missing delivery windows, that's a sign that the left hand is not talking to the right hand. Somewhere, information is not flowing and there might be too much time between the confirmation and when the warehouse starts to package up the item for shipping. Or, perhaps you are confirming orders that are not actually in stock. If so, you will need to improve communication and organization in the warehouse.

The bottom line is that no matter how long your business has been around or how successful it is, there are always a million factors in logistics that can go awry. Problems with PO confirmation and shipping indicate it's time to make some fundamental changes to your logistics process.

Better Track Your Data

Even if you’ve got a great inventory operation, you still may struggle with POs if you aren’t tracking data well enough. For example, data could show you how POs ebb and flow during certain times of the week, month, or year that isn’t obvious with day-to-day operations. You need access to vendor data to grow your business.

Unfortunately, Amazon makes it quite difficult to access this data. You have to log in to Vendor Central, find the report, manually download it for that day, and do this with report after report, and then combine all of them manually.

Reason Automation was created to solve exactly this problem. Read more in our eBook below.

READ MORE:

Improve Profitability

Using Product-Level Operations Data from Vendor Central

As an Amazon vendor, you drive profitability with three levers: 1) selling as much of your product to Amazon as possible, 2) minimizing chargebacks, and 3) optimizing your product portfolio.

This guide will provide frameworks to improve your Amazon business's profitability and help you leverage Vendor Central's Operations tables for deeper insight.